There are a wide array of laboratory applications that use membrane filtration processes and for various reasons. Some of the common applications include: Gas, oil, alcohol or bacteria filtration Ground water and waste water filtration Industrial water filtration Chemical filtration Beverage filtration Tissue culture media filtration

2022/04/14 · Phases of Membrane Filter Press Cycle 1 - Filling Stage Filling Stage: The Mash enters the chambers through a feed pump. 2 - Filtration Stage Filtration Stage: Once the chambers are full, the Mash that is being pushed by the feed pump will force the Wort out from the chambers. The Filter Plates and Filter Cloths will capture the Mash Grains.

These hydrophilic, low protein binding, PES membrane filters are ideal for tissue culture media sterilization, life science and microbiology fluid applications, clinical, and general filtration. Features: Strong and durable for easy handling Lot-to-lot consistency provides reproducible results every time Uniform pore structure Low protein binding

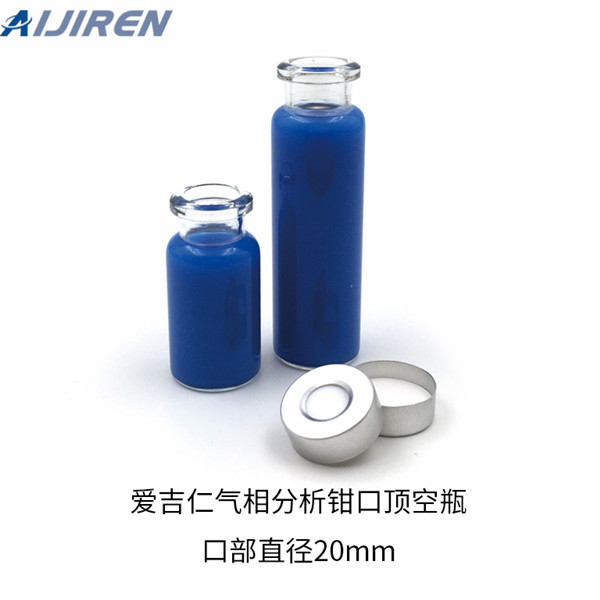

![<h3>メンブレンフィルターとは | 富士フイルム [日本]</h3>](/wp-content/themes/aijiren/load/12/Brand new 20ml headspace vials.jpg)

The membrane is asymmetric and reinforced with nonwoven cellulose making them very durable. They are available in two pore sizes: 0.45 μm and 0.2 μm and several diameters, making it easy to fine regenerated cellulose filter for almost every need. Solvent and pH resistant Fast flow rates Available in two pores sizes and multiple diameters Shop Now

Membrane filtration (MF) is a pressure-driven separation process that employs a membrane for both mechanical and chemical sieving of particles and macromolecules (Benjamin and Lawler, 2013). From: Advances in Chemical Mechanical Planarization (CMP), 2016 View all Topics Add to Mendeley Download as PDF About this page

There are multiple membrane materials currently employed for liquid/liquid, liquid/solid and gas/solid separation: PES membrane, PTFE membrane, PVDF membrane, NY membrane and PP membrane. PES (Polyethersulfone) Membrane -- Hydrophilic PTFE (Polytetrafluoroethylene) Membrane -- Filtration and Textile PVDF (Polyvinylidene Fluoride) Membrane

2022/07/26 · Nanofiltration: Medium-pressure membrane technology for separation, concentration, and demineralization of liquids. Reverse Osmosis Technology Reverse Osmosis: Medium and high-pressure membrane technology for water purification and product concentration.

2018/04/09 · Polymeric membranes are the most commonly used membrane material and one of the most recognized global suppliers is PCI Membranes, a Filtration Group company. PCI Membranes ultrafiltration membrane technology for the juice industry was developed about 30 years ago and has been incorporated as a new method to replace rotary vacuum drum filters.

Operation Principle Of Membrane Plate Operation: 1. Feeding Of Filter Press During the feeding operation the membranegoes inbackward direction under low tension.Feeding operation is completed when the required feed pressure is obtained. 2. Sqeezing Of Filter Cake

GSWP04700 Millipore MF-Millipore™ Membrane Filter, 0.22 µm pore size Download Zoom 47 mm diameter, mixed cellulose esters (MCE) membrane, hydrophilic, white, 100 discs MSDS (material safety data sheet) or SDS, CoA and CoQ, dossiers, brochures and other available documents. SDS Technical Information User Guides GSWP04700